Case files can be found here:

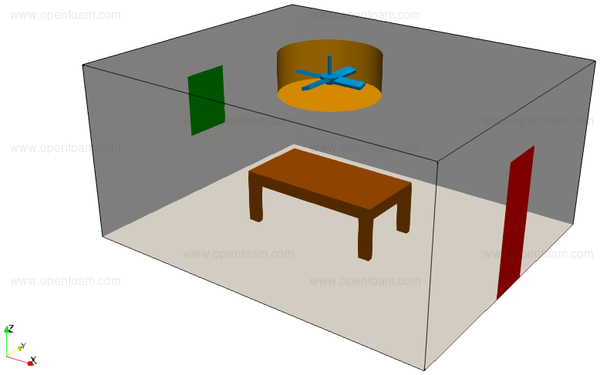

The geometry for this tutorial consists of

The mesh is created with snappyHexMesh using STL surfaces located in the constant/triSurface directory.

surfaceFeatureExtract

The process begins by extracting features from the STL files (dictionary can be found in system/surfaceFeatureExtractDict).

blockMesh

This command creates an initial block structured mesh with our starting mesh resolution (dictionary can be found in system/blockMeshDict).

snappyHexMesh -overwrite

This command refines the initial mesh at the STL surfaces as well as the extruded features (dictionary can be found in system/snappyHexMeshDict). Layer addition is not utilized in this tutorial for simplicity purposes. Usual snappyHexMesh settings are utilized for a coarse mesh here. One important entry can be found in the refinementSurfaces sub-dictionary:

AMI

{

level (2 2);

faceType boundary;

cellZone rotatingZone;

faceZone rotatingZone;

cellZoneInside inside;

}

This defines a cellZone called rotatingZone, which will later define the rotating cells. Additionally we define a boundary, which will be later used to define the interpolation faces between rotating and non-rotating regions.

renumberMesh -overwrite

This commands restructures the mesh for better calculation performance.

createPatch -overwrite

This command converts the boundary AMI to an arbitrary mesh interface (hence AMI), where during the simulation the interpolation of fields between rotating and non-rotating cells will take place (dictionary can be found in system/createPatchDict).

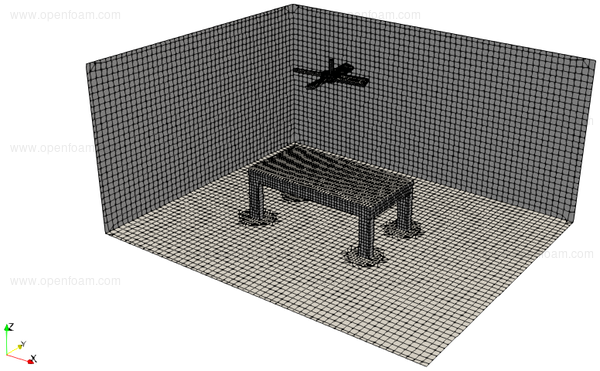

After these steps you can visualize your mesh in ParaView:

Here you can see the rotating and non-rotating regions of the mesh:

Now we move from the folder mesh to the folder case.

fixedFluxPressurefixedFluxPressurefixedFluxPressurefixedFluxPressureturbulentIntensityKineticEnergyInlet with 5% turbulence intensitykqRWallFunctionkqRWallFunctionkqRWallFunctionturbulentMixingLengthFrequencyInlet with 1.2m mixing lengthomegaWallFunctionomegaWallFunctionomegaWallFunctionnutkWallFunctionnutkWallFunctionnutkWallFunctioncellZone rotatingZone; - This was defined in snappyHexMeshDict to define the rotating cells.solidBodyMotionFunction rotatingMotion; - rotating mesh movementorigin (-3 2 2.6); - origin of the axis of rotation of cells (can be anywhere on the rotation axis of the fan)axis (0 0 1); - direction of the rotation axis (here: z-direction)omega 10; - angular velocity of rotation in rad/s= (corresponds to ~95.5 rpm)omega 20;The simulation employs the pimpleFoam application, in parallel.

decomposePar

With this command you divide your mesh and your fields onto multiple processors.

mpirun -np 4 pimpleFoam -parallel > log.pimpleFoam &

With this command you start your simulation on four cores. If you want to use a different number of cores you have to change the number (here: 4) to you choice. Also don't forget to change the settings in system/decomposeParDict!

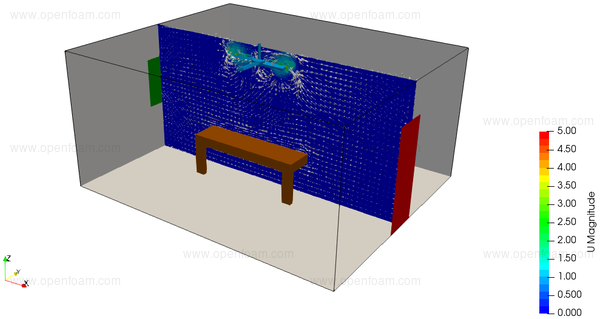

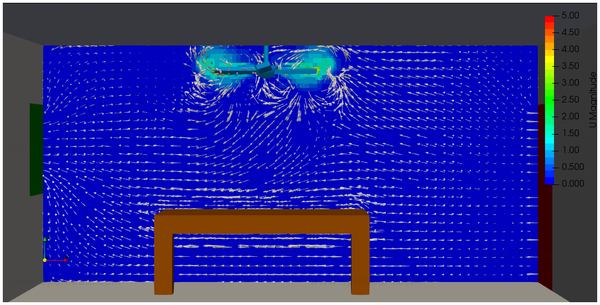

Here you see the flow after t = 0.64 s.

Velocity magnitude and vectors on a y-normal plane:

Close-up of velocity magnitude and vectors on a y-normal plane:

| Contributors to this page | Jozsef Nagy |

| Would you like to suggest an improvement to this page? | Create an issue |

Copyright © 2019 OpenCFD Ltd. and Contributors